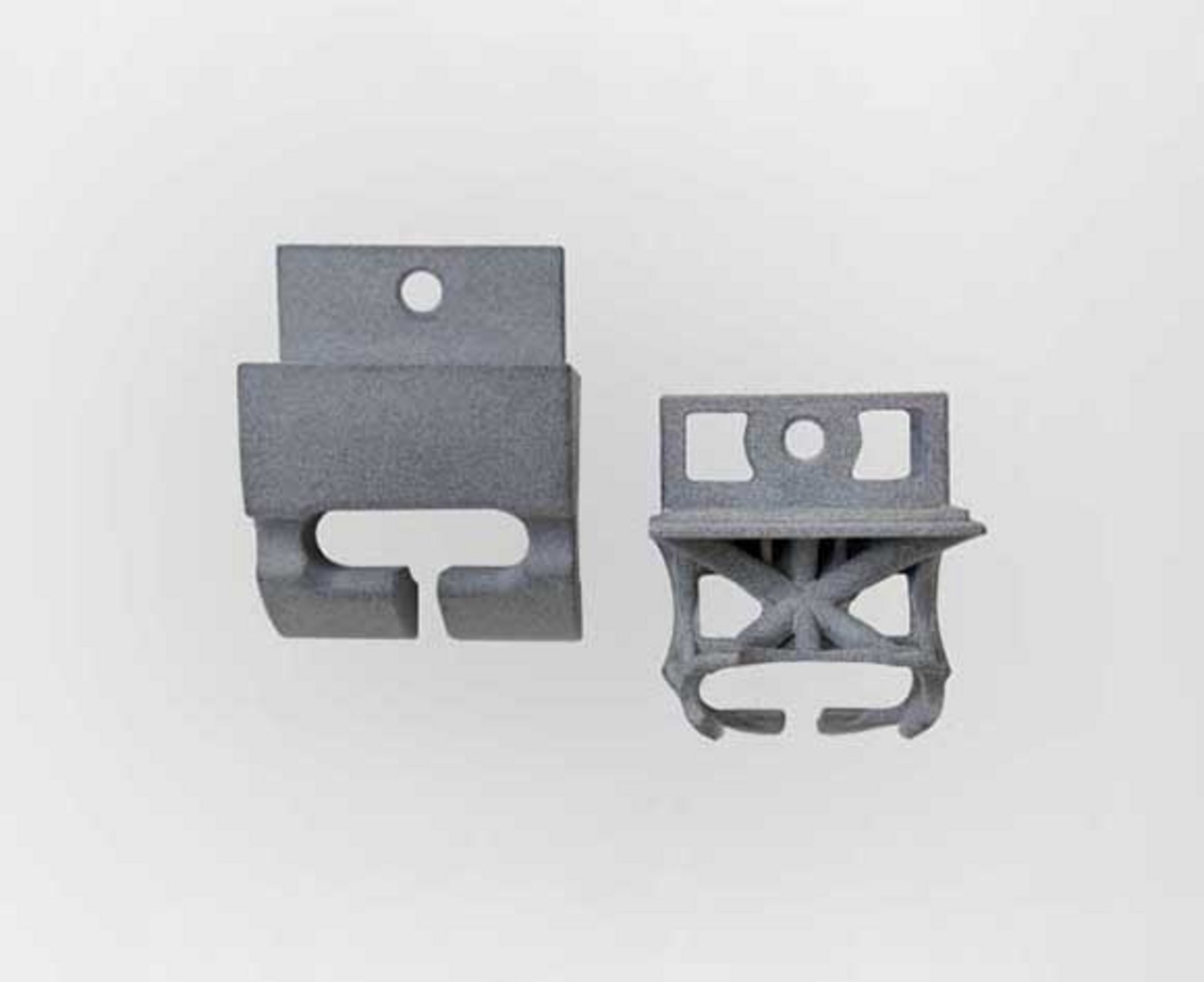

MULTI JET FUSION technology for high-quality components

Multi Jet Fusion, or MJF for short, is currently the fastest and most economical 3D printing process for plastics. It ensures extremely high-quality prototypes and functional parts – and can be used in series production. This technology, in combination with selected materials, is the ideal choice for customized high-end components. With one of the most advanced machines on the market, the HP Multi Jet Fusion 5210, SPÄH offers decisive advantages, especially in terms of volume production.

Two first-class materials:

PA12 AND PP

In addition to the material polyamide 12 (PA12), which is characterized by high stability and impact resistance, we are also the first company to combine MJF technology with polypropylene (PP). Incredibly diverse and customized components are possible with these materials.

Stability

Stiffness

UV/chemical resistance

Temperature stability

Stability

Stiffness

UV/chemical resistance

Temperature stability

Our finishing options

For even more customized results, we can additionally machine your component – for example, to meet your custom requirements – on our turning and milling centers. Combination parts, such as inserted sealing lips, are also no problem for us. Naturally, we can smooth your component’s surfaces, as well as dye and paint them in various shades as required.

3D printing with polypropylene

Polypropylene is used in around 70% of all injection molding applications – because the advantages of this semi-crystalline thermoplastic speak for themselves. In addition to favorable low costs, polypropylene also offers exceptional chemical resistance, excellent plasticity, greater elongation and durability with low moisture absorption. SPÄH is the first additive manufacturing specialist to offer industrial 3D printing using the Multi Jet Fusion manufacturing process with polypropylene for the general market.